Wheel Loader

1. OPERATING WEIGHT

The total mass in kilograms (pounds) of the machine as specified and fully serviced, including a full fuel tank and 80 kg (175 Ib) operator.

2. BUCKET CAPACITY (BY SAE)

The bucket capacity of wheel loaders is calculated as follows:

The struck capacity is defined as the volume of material retained in the bucket after a heaped load is struck by drawing a straight edge across the width of bucket with one end of the straight edge resting on the cutting edge and the other end resting on the uppermost portion of the bucket back sheet or spill guard. The struck capacity (Vs) can be expressed by the following equation:

Where c is the length on a normal to the strike line. On one end it is terminated by the assumed crest of the material.On the other end it is terminated by the intersection with a line from the bit or cutting edge tip to the base of the spill guard.

This method applies primarily to irregular buckets having parallel sides and a cutting edge parallel to the edge of the spill guard or back sheet. Moderately clipped spill guard corners will introduce no appreciable errors.

3. RATED LOAD

The rated load (operating load) will not exceed 50% of the TIPPING LOAD for wheel loaders or 35% of the TIPPING LOAD for crawler loaders, and will be considered as operating under the following conditions:

1. Lifting ability of the machine in all bucket positions to be no less than the specified operating load.

2. Bucket attachment of specified size and type.

3. Maximum travel speed of 6 km/h (3.7 mph).

4. Operating surface.

(a) Shall be hard, moderately smooth and level for wheel loaders.

(b) General operating conditions of crawler loaders are such that they normally are not operating on hard, moderately smooth level surface.For this reason, the rating on crawler loaders is set at the lower figure of 35%.

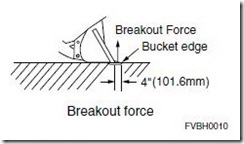

4. BREAKOUT FORCE

Breakout force in kilograms (and kilo-Newton or pounds) is the maximum sustained vertical upward force exerted 100 mm (4 in) behind the tip of the bucket cutting edge and is achieved

through the ability to lift and/or roll-back the bucket about the specified pivot point under the following conditions:

(a) Machine with transmission in neutral.

(b) All brakes released.

(c) Unit at standard operating weight, rear of machine not tied down.

(d) Bottom of cutting edge parallel to and not more than 25 mm (1 in) above or below the ground line.

(e) When bucket circuit is used, the pivot point must be specified as the bucket hinge pin, and the unit blocked under the bucket hinge pin pivot point in order to minimize linkage movement.

(f) When the lift circuit is used, the pivot point must be specified as the lift arm hinge pin.Wheel loaders shall have front axle blocked to eliminate change in position of pivot pins due to tire deflection.

(g) If both circuits are used simultaneously, the dominating pivot point listed in (e) or (f) must be specified.

(h) If the circuit used causes the rear of the machine to leave the ground then the vertical force value required to raise the rear of the machine is the breakout force.

(i) For irregular shaped buckets, the tip of the bucket cutting edge, referred to above shall mean the farthest forward point of the cutting edge.

5. STATIC TIPPING LOAD

The minimum mass in kilograms (pounds) at the center of gravity of the SAE rated load in the bucket which will rotate the machine to a point where, on the crawler units, the front track rollers are clear of the track and, on wheel loaders, the rear wheels are clear of the ground under the following conditions:

(a) Maximum bucket rollback.

(b) Center of gravity of load at the maximum forward position in the raising cycle.

(c) Machine at operating weight and equipment as specified.

Articulated steer loader shall be in full turn

position (specify angle).

6. LIFTING CAPACITY

The maximum mass in kilograms (pounds) at the center of gravity of SAE rated load in the bucket that can be lifted at a specified height with the bucket positioned to retain maximum load under the following conditions:

(a) Machine with rear end tied down.

(b) Machine at operating weight and equipment as specified.

7. HYDRAULIC CYCLE TIMES

• Raising Time — The time in seconds required to raise the bucket, rolled back, from the ground level

position to full height with the specified SAE operating load.

• Lowering time — The time in seconds required to lower the empty bucket from the full height to a level position on the ground.

• Dump Time — The time in seconds required to move the bucket from the load carrying position at maximum height to the full dump position while dumping the specified SAE operating load.

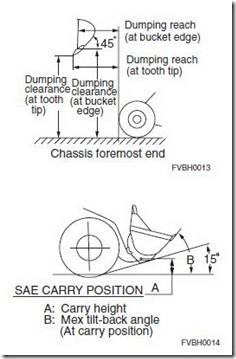

8. DUMPING CLEARANCE AND REACH

• Dumping clearance — The vertical distance in millimeters (inches) from the ground to the lowest point of the cutting edge with the bucket hinge pin at maximum height and the bucket at a 45 degree

dump angle. If the dump angle is less than 45 degree, specify the angle.

• Dumping reach — The horizontal distance in millimeters (inches) from the foremost point on the machine (including tires, tracks, or loader frames) to the rearmost point of the bucket cutting edge with

bucket hinge pin at maximum height and bucket at a 45 degree dump angle. If the dump angle is less than 45 degree, specify the angle.

9. CARRY POSITION

The vertical distance from the ground in millimeters (inches) to the centerline of the bucket hinge pin, with the angle of approach at 15

degree ( Picture Above )

( Source : Komatsu Specifications Handbook 28 )

0 comments:

Post a Comment